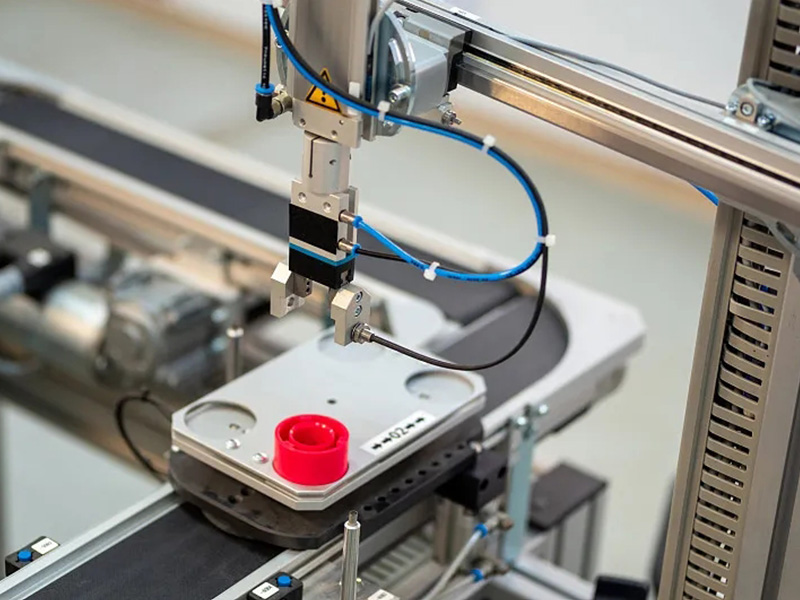

Application Description

Industrial automation represents the trend towards extensively employing automatic control and adjustment devices in industrial production to replace manual operation of machinery and machine systems for processing and manufacturing. Bearings in automated equipment are typically used in the joints and rotating components of such machinery, necessitating exceptionally high precision requirements. Precision cross-roller bearings offer 3-4 times greater rigidity than standard angular contact ball bearings.

Solution Features

High-precision design with minimal operational clearance ensures exceptional positioning accuracy, meeting the demands for precise transmission and positioning in automated equipment.

Low friction coefficient and minimal operational noise adapt to the high-frequency start-stop and continuous operation conditions of automated equipment, enhancing overall performance.

Superior protective properties effectively isolate contaminants such as dust, cutting fluids, and oil residues, preventing internal bearing wear and lubrication failure to extend service life.

High rigidity and load-bearing capacity enable stable support for both radial and axial loads in automated equipment, ensuring operational stability.

Strong dimensional compatibility allows precise matching to diverse automated equipment models, accommodating components such as robotic arm joints, linear guides, and servo motors, offering broad versatility.

-

View details ➜

View details ➜The mining, mineral processing and cement production industries operate under some of the harshest

-

View details ➜

View details ➜During papermaking, equipment frequently comes into contact with moisture and pulp residues. Traditi......

-

View details ➜

View details ➜Equipment within this industry frequently operates under demanding conditions characterised by high ......

-

View details ➜

View details ➜Construction machinery operates in dusty, high-load environments where its articulated joints freque......