-

-

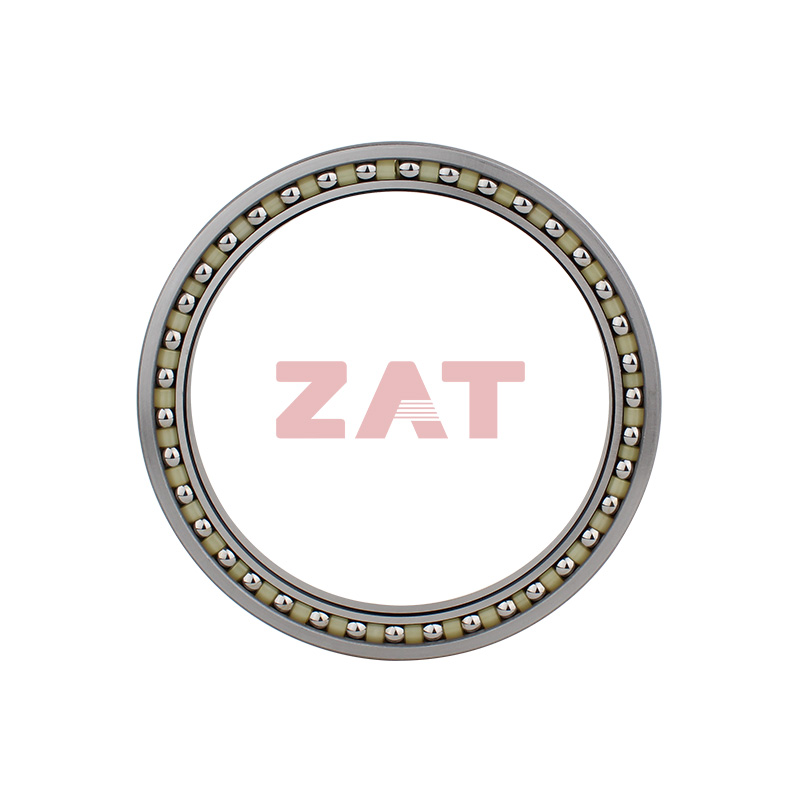

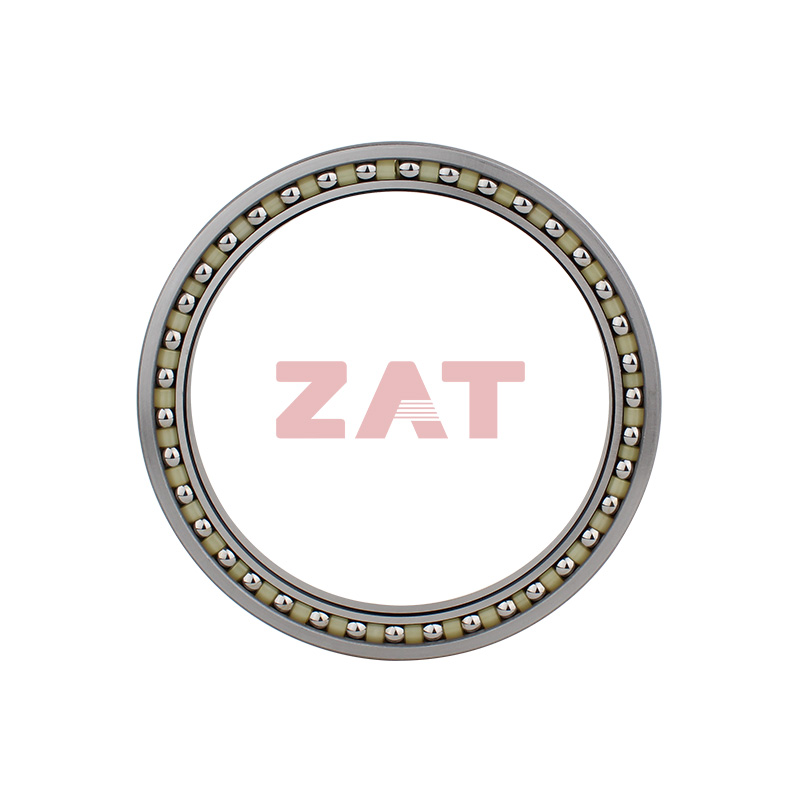

BA115-1 Excavator bearing

Excavator bearings are mechanical components utilised in the undercarriage and slewing mechanisms of excavators. Suitable for heavy-duty excavators and mining equipment operating under prolonged continuous duty, they deliver high operational stability, responsive performance, and extended service life.

High load capacity

High impact resistance

High fatigue resistance

Sealed and dustproof

Low friction

-

0.000.00

-

Excavator bearings are mechanical components utilised in the undercarriage and slewing mechanisms of excavators. Suitable for heavy-duty excavators and mining equipment operating under prolonged continuous duty, they deliver high operational stability, responsive performance, and extended service life.

High load capacity

High impact resistance

High fatigue resistance

Sealed and dustproof

Low friction

Product Description

Excavator bearings are mechanical components utilised in the travel mechanisms, slewing mechanisms, and other critical areas of excavators. Primary types include travel bearings, slewing bearings, roller bearings, gear bearings, and rotary support bearings. Installation involves the assembly of travel motor bearings and travel drive bearings, necessitating the use of hydraulic excavator bearing housing installation aids for precise positioning. Compatibility with different machine models is achieved by replacing the cap to accommodate varying bearing dimensions.

Product Features

- Sealed dust-proof design prevents soil and grit ingress into raceways, reducing wear and corrosion risks.

- Precise installation positioning facilitates straightforward disassembly and maintenance, delivering extended service life.

- Impact and fatigue resistance, featuring cages constructed from high-strength brass or alloy steel for superior deformation resistance.

- Low friction coefficient minimises operational resistance, ensuring responsive excavator movements and reduced hydraulic system energy consumption.

- Exceptional load-bearing capacity, with rated static load 3–5 times that of standard industrial bearings, suitable for heavy-duty applications in mining and infrastructure projects.

Product Parameters

| Model | d | D | B | Model | d | D | B |

| model | 100 | 160 | 48 | BA200-10 | 200 | 280 | 38 |

| 105BA14 | 105 | 144 | 14 | BA205-1 | 205 | 295 | 40 |

| BA115-1 | 115 | 145 | 15 | 210BA29V | 210 | 295 | 35 |

| 120BA16 | 120 | 165 | 22 | AC423040-1 | 210 | 300 | 40 |

| BD130-1SA | 130 | 166 | 34 | BA220-6WSA | 220 | 276 | 26 |

| DE2622PX1 | 130 | 166 | 34 | BA220-6SA | 220 | 276 | 26 |

| BD130-16WSA | 130 | 166 | 41 | BA220-1 | 220 | 280 | 28 |

| SF2812VPX1 | 140 | 175 | 17.5 | BN220-1 | 220 | 280 | 28 |

| SF2912 | 145 | 200 | 27.5 | CR4411PX1 | 220 | 290 | 32 |

| BA152-2036 | 152 | 203 | 26 | SF4411VPX1 | 220 | 290 | 32 |

| BD155-1WSA | 155 | 198 | 48 | SF4444VPX1 | 220 | 295 | 32 |

| SF3227VPX1 | 160 | 200 | 10 | B-SF4454PX1 | 220 | 295 | 33 |

| SF3215 | 160 | 200 | 20/28 | BA222-1WSA | 222 | 273 | 26 |

| BD165-6A | 165 | 210 | 52 | BA4531 | 225 | 315 | 40 |

| BA16519A | 165 | 203 | 19 | AC4531 | 225 | 315 | 36 |

| BA168-1 | 168 | 205 | 20 | AC4629 | 230 | 290 | 27 |

| BA180-2256 | 180 | 225 | 21.5 | AC4630 | 230 | 300 | 35 |

| 180BA-2256SA | 180 | 225 | 22 | BA230-7A | 230 | 300 | 32 |

| SF3607VPX1 | 180 | 225 | 21 | BA230-7ASA/WSA | 230 | 300 | 35 |

| BA180-4WSA | 180 | 250 | 33 | SF4615VPX1 | 230 | 300 | 35/33 |

| 180BN19W | 180 | 250 | 33 | SF4631VPX1 | 230 | 310 | 39 |

| SF3650VPX1 | 182 | 214 | 18 | AC4631 | 230 | 310 | 40/39 |

| 184BA-2251 | 184 | 226 | 21.5 | AC463240 | 230 | 320 | 40 |

| BA184-2251 | 19 | BA230-2A | 230 | 320 | 40 | ||

| BA195-3A | 195 | 280 | 36.5 | SF4820VPX1 | 240 | 310 | 33 |

| SF4007VPX1 | 200 | 250 | 24 | SF4826VPX1 | 240 | 310 | 33 |

| BA200-7B | 200 | 250 | 25 | SF4852VPX1 | 240 | 310 | 33 |

| SF4019VPX1 | 200 | 260 | 30 | SF4815VPX1 | 240 | 310 | 33/34 |

| 200BA27V-2 | 200 | 270 | 33 | SF4831VPX1 | 240 | 310 | 25/33.4 |

| BA210-10 | 200 | 280 | 38 | BA4852PX1 | 240 | 310 | 33 |

| BA200-10 | 200 | 280 | 38 | BA240-3ASA/WSA | 240 | 310 | 33.5 |